On May 30, Chris Osborn alerted me on Twitter about a Reddit post announcing a Digital Equipment Corporation (DEC) PDP-11/34A computer system available for free in Indio, CA, about an hour and a half away from where I live. That sounded right up my alley, so I contacted the owner to see if I might be the lucky guy to adopt it.

After the owner got back to me, I learned that he had acquired it for $30 in an auction. He had been planing to take it with him in his upcoming move to the midwest, but then got an unpleasant surprise when he went to pick up his rental moving truck from Penske and it didn’t have the lift gate that he was expecting. He couldn’t take the system with him, and he needed to find a new home for it very quickly! He shared a picture of the system, and I could see that it was a nicely-configured system consisting of a PDP-11/34A, a Kennedy 9000 9-track magtape drive, a System Industries 9400 SMD disk controller, and a Fujitsu M2284K 160M hard drive, all in a nice equipment rack.

After seeing a picture of the system, I quickly determined to grab, uh, I mean rescue it. I arranged with the seller to pick it up on Sunday June 9, confirmed that my Dad would be willing to help me, and started making plans. At first I planned to show up in my Toyota Tundra pickup truck, disassemble it, and load up the pieces. After thinking about that a bit, I decided it would be a much better idea to rent a small box truck with a lift gate so we could move it upright in one piece. It was expected to weigh around 500 pounds, and would break down into pieces weighing around 100 pounds each! I made a reservation with Penske to rent a 16′-18′ box truck with a lift gate. I also downloaded as many relevant manuals as I could find so I could study how to engage the shipping locks on the hard drive, and to just learn more about the system components in general.

I started to get anxious on Saturday morning when the local Penske agent called me to say she was having trouble finding a truck with a lift gate, and was wondering if I could use a truck with a ramp. No, I absolutely needed a lift gate! I was relieved when I arrived at Penske that afternoon and they had a lift gate truck waiting for me. I brought it home and began preparing to pick up my Dad the next morning and head to Indio.

When my Dad and I arrived in Indio on Sunday morning, I was excited to see the system in person. I took stock of what was there, got the hard drive shipping locks engaged, and wrapped it all in pallet wrap to keep things from flapping about during transport. It had been moved who knows how many times without the shipping locks engaged, including at least one ride on its side in the owner’s pickup truck, so hopefully the hard drive is still happy. Mummifying the rack with pallet wrap made me dizzy! It didn’t help that it was a record-breakingly hot day of around 104ºF.

- First Sight of the System

- Rear View of the System

- Big, Dusty Hard Drive!

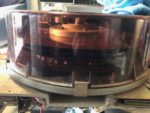

- Cover Over the Spindle Pulley

- Spindle Locked

- Drive Head Lock

It was when we rolled the system onto the lift gate that everything went sideways… literally! The rack was about an inch and a half taller than the box truck’s roll-up doorway, so it wasn’t going to go in upright like I had planned. We figured out how to get it turned on its side and into the truck with help from the lift gate, some really dodgy ratchet strap rigging, a lot of grunting, and a few rest breaks. Did I mention that it was around 104ºF that day? By this time, it felt more like 104ºC!

- Mummified PDP-11/34A

- Oh, No… It’s Too Tall!

- Dodgy Rigging and a Good Push

- Careful… Careful…

- Now the Shoving Begins

- More Dodgy Rigging

Getting it tied down so it wouldn’t slide around while driving was another problem. I had been expecting to lash the upright rack against a wall of the box using the E-track, and bought straps and fittings to do that. But the truck didn’t have any tie down points at floor level to secure the rack in place on its side. My Dad and I managed to get it tied in place with the straps and fittings that we had, but it all looked pretty how-ya-doing.

After all of that work loading up the rack, we were pretty hot and tired. We stopped at Denny’s to drink water, cool down, drink more water, eat, and drink more water before heading back to Riverside.

Once we got home, we were relieved to see that the rack hadn’t shifted at all during the drive. Then we got to work unloading it. Even with the help of my tractor, that turned out to be even harder than loading it was! Eventually we managed to get it upright on the tractor’s pallet forks, and then we placed it on my front porch. By this time, were were completely exhausted and on the verge of heat stroke, so we called it good and went to my folks’ place to rest and order a pizza delivery.

- Back Home!

- Tug-of-war

- Unloading

- Half Way There

- On the Forks

- On the Porch

I had to return the truck the next day, and I decided to take a day off from work to rest up. I managed to get the rack over the threshold of my doorway by myself, though it took a couple hours. Fast-forward a few weeks to today, and it’s still sitting in my living room just inside the doorway. Maybe this weekend I’ll manage to tile-puzzle it through my cluttered house into my electronics lab room?

Tape Drive Secret Menu

With the system inside my house, I began the long (and fun!) task of cleaning it, identifying what’s in it, cleaning some more, replacing bad capacitors, cleaning some more, fixing damaged cabled, cleaning some more (it is so dusty!), and getting it running. So far I’ve identified and replaced two bad electrolytic filter capacitors in the computer’s -15V regulator, replaced the rubber tires on the tape drive hubs (they’re just dash-336 O-rings; I ordered these ones from McMaster-Carr), repaired some damaged ribbon cables, and performed some preliminary testing.

- Computer Dataplate

- Computer Configuration Label

- Computer’s Cards

- Hard Drive Dataplate

- Ugly Console Cable

- Tape Drive Dataplate

- Plessey 8-Port Serial Card

- Emulex TC11 Tape Interface

- System Industries 9400-6061

- Bootstrap Card

- Console Interface and Real-Time Clock

The computer is configured with the following cards:

- M8265 & M8266 KD11-EA CPU

- M9301-YF UNIBUS terminator + bootstrap

- M7859 KY11-LB programmer’s console interface

- M7850 MM11-BP/CP parity card

- Two aftermarket 64k x 18 RAM cards

- Emulex SC11 SMD hard drive interface (not connected to anything)

- M920 UNIBUS connector

- M7856 DL11-W real-time clock and serial console interface

- Two Plessey PM-DZ11A 8-port serial cards

- Emulex TC11 tape controller with PE data card for 800/1600 BPI support

- System Industries 9400-6061 SMD controller, connected to the Fujitsu M2284K hard drive

- M9302 UNIBUS terminator

- Five G727A bus grant continuity cards in column D of unused slots

- AC Power Entry Module

- Power Supply Hinged Open (Bottom)

- Power Supply Hinged Open (Side)

- Lovely Sangamo Electrolytic Capacitors

- Testing and Reforming Capacitors

- System Industries 9400

- SI 9400 ROM Card

- SI 9400 Interface Cards

- SI 9400 Power Supply

- Tape Drive Service Access

- Tape Drive Motors

- Tape Drive Electronics

- Excavating the Hard Drive

- Drive Heads

- Drive Platters

- Drive Head Positioner

- Tape Loaded

I cleaned the whole tape path thoroughly with tape head cleaner before I let the tape drive touch one of my magtapes. The handy test controls hidden behind the drive’s nameplate let me test the tape transport (minus reading/writing data) even though I didn’t have the computer up and running yet at this point. I was happy to see that it loaded a tape just fine, the hub servos seem to be working, and tape motion and the tape end sensors appear to be good.

Loading a Tape

After my replacement capacitors arrived and I got the CPU chassis reassembled, I was able to power it up and get the expected console emulator prompt on an attached terminal. The PDP-11/34A is alive!

- Replacement Capacitors

- -15V Regulator Repaired

- New Dust Filter Fitted

- Programmer’s Console Reinstalled

- First Successful Power-Up!

- Replacing Foam on Cable Clamp

- Restored Cable Clamp

- Cable Clamp and Console Cable

- Bottom of Rack

- Hard Drive Power Supply

- Ample Cables

At this time, I’ve at least powered up everything except the System Industries 9400 SMD disk controller. The CPU boots up from its bootstrap board and presents its console emulator prompt, and the tape reels start moving when I command the computer to try to boot from the tape drive (I just had a blank tape mounted, so I don’t know yet whether it can read and write). I’ll need to move the whole rack into a different room where I have a 115VAC 30A circuit before I can power up everything simultaneously and see if the computer can talk to the hard drive. Will it actually boot from the hard drive? I can hardly wait to find out!

PDP-11/34A Tape Drive Test

This is super cool.

I can’t get the videos to play full sized in any browser, they are embedded at something like 120×120 pixel size.

Absolutely fantastic report that you have constructed, and we who visit this page are gratified by your effort. Thank you.

This is beyond cool – thank you for sharing this story! I’m so happy that such a rare and important machine was saved from the scrapper and lives on. Well done!

where’s the ethernet port?

It didn’t come with one. Until I get the hard drive working and find out what is on it, I can’t even assume that it was running an operating system with any concept of networking. I think I have a DEC Ethernet card that I may put in it eventually. I have a UniBone kit on the way from Germany, so I’ll probably get this machine doing more than toggled-in test code for the first time by emulating RL02 drives with the UniBone. I’ll try tunning RT-11 first since that’s what I’m familiar with. I’ll probably try other operating systems like RSX-11 later. Maybe even an early UNIX?

Aloha Mark, nice to meet you! I know, I was being facetious. If I could get that lovely beast installed in my living room, it would be worth the divorce of my wife! Good Luck!

Billy

You might have been joking, but I already have a DECnet Phase IV node number and a host name reserved for it. Eventually I will try running RSX-11M on it and it will visit HECnet as node COLLIE::

I still have a 11/34A box In My garage that still powers up. Over the years I lost the periphials that went with Itfrom moving, and not having room or time to move everything else.So about once a year I manage to dig a path to the box and plug it in to see if it smokes.LOL no smoke yet! one of these days i might be able to make some form of storage so I can do some programming on the real thing.

Very cool! I hope you can make it do more again. If you aren’t set on obtaining original storage peripherals for it, then you might consider using a Unibone: http://retrocmp.com/projects/unibone

I have a Unibone kit that I plan to try in my PDP-11/34A once I get around to building it.