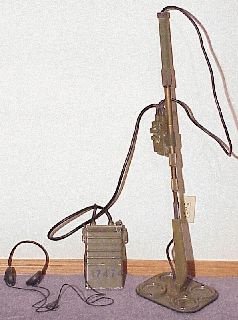

Two items not shown in the above pictures are the canvas bag which lets you attach the electronics package to a standard military pistol belt (I got mine after I wrote this article), and a protective cover for the detector head (which I haven’t found yet).

Battery Fabrication

The AN/PSS-11 originally used a 10.4V mercury oxide battery called the BA-1389/U (NSN 6135-00-691-3603). This battery was composed of 8 “camera-style” button cells connected in series to form a battery pack about 0.65″ in diameter and about 5.2″ long. Each cell is connected to the adjacent cells by drawn metal cups which are spot-welded to the cell terminals, and the whole assembly is covered in a shrink-wrapped plastic tube. Note that in mercury oxide cells, the case is positive and the “bump” is negative. The original battery has to be over 70°F to operate properly, so a battery adapter is supplied which allows the operator to tuck the battery inside his clothes when the temperature is too low. According to the tech manual, the mine detector is designed to operate from 7.25 to 10.8 volts DC. The BA-1389/U has a rated life of 35 hours of continuous use.

Due to environmental concerns, the Army began developing replacements for mercury-containing batteries such as the BA-1389/U around 1995, and by 1997 the BA-3389/U (NSN 6135-01-442-4580) was deployed as a replacement. The new battery uses the more common, and supposedly more environmentally-friendly alkaline battery chemistry.

For collectors, the bad news is that you can’t buy a BA-1389/U or BA-3389/U battery at the local grocery store. The good news is that it’s not too hard to come up with an acceptable substitute. The battery is a simple cylinder with a contact at each end; unlike a lot of other military batteries, you don’t need to scrounge or build any funky connectors. Based on Mike Murphy’s suggestion, I used a pair of Eveready 523 cells. I ordered mine from Mike; I don’t know how common they are. They are not listed on Eveready’s web page, so I’m wondering if they were discontinued. The packaging says that they replace batteries PX21, RPX21 and V21PX.

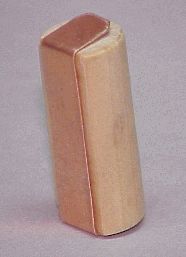

The 523 cells are alkaline cells meant for photographic applications, and generate about 4.5 volts. They are about the right diameter, and two of them will provide enough voltage to run the metal detector. They are about 1.96″ long, so a pair of them isn’t as long as the original battery. Thus, it’s necessary to make a 1.3″-long “dummy battery” to fill in the extra space in the battery compartment. It’s pretty easy to make one from common junk you may find in your garage (or at the local hardware or hobby store). It’s not necessary to assemble the cells into a battery pack; you can just insert them in the mine detector’s battery compartment with the dummy battery. Your milage may vary if you assemble a battery pack using a different cell.

The copper strap material that I used was left over from grounding my ham shack. You should be able to substitute any light-gauge copper or brass sheet or strip material from a hobby or hardware store. If you have access to an engine lathe, you might want to make a fancier dummy battery out of brass or copper rod (don’t forget to insulate it, though!), or even a slug of nylon, bakelite, etc. with a copper or brass rod through the center.

Using the AN/PSS-11

Here are some scanned excerpts from TM 5-6665-202-13, Operator, Organizational and Direct Support Maintenance Manual, Detecting Set, Mine: Aural Indication […] AN/PSS-11:

- Mine detector set with shipping dimensions

- Battery, removal and installation

- Preparations for search operation

- Controls

- Starting and stopping the mine detector set

- Variometer phasing and sensitivity checks (1/2)

- Variometer phasing and sensitivity checks (2/2)

- Detector head, positions and use

- Battery adapter, removal and installation

Schematic Diagrams

References

- http://www.monmouth.army.mil/cecom/lrc/tools/spr95.html (link no longer works)

- http://www.monmouth.army.mil/cecom/lrc/tools/fall97.html (link no longer works)